A buttweld fitting is a weldable pipe fitting that allows for change of direction of flow, to branch off, reduce pipe size or attach auxiliary equipment. Forged Steel buttweld fittings are manufactured in accordance with ANSI / ASME B16.9.

Butt weld fittings are available as elbows, tees, caps, reducers and out lets (olets). These fittings are the most common type of welded pipe fittings and are specified by nominal pipe size and pipe schedule. Buttweld fittings use seamless or welded pipe as the starting material and are formed (through multiple processes) to get the shape of elbows, tees and reducers etc. Just as the pipe is sold from Schedule 10 to Schedule 160, butt weld pipe fittings are sold the same way. Welded butt weld fittings are more common in stainless steel due to cost advantage. Sch 10 fittings are also more common in stainless steel butt weld fittings.

Common material for butt weld fittings are A234 WPB (A & C also available), High Yield Carbon Steel, Stainless Steel 304 and 316 and Nickel Alloys.

-

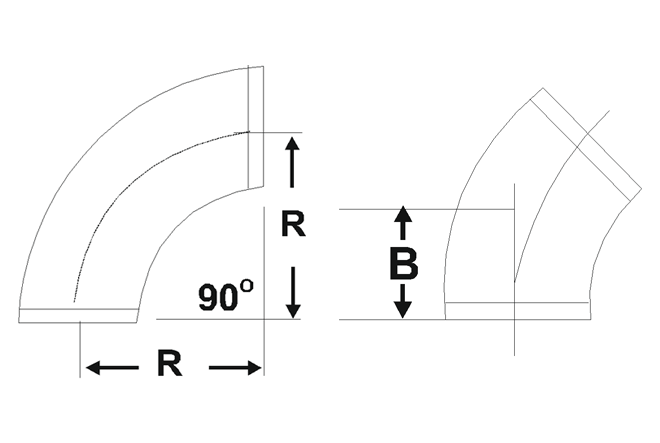

Elbows

-

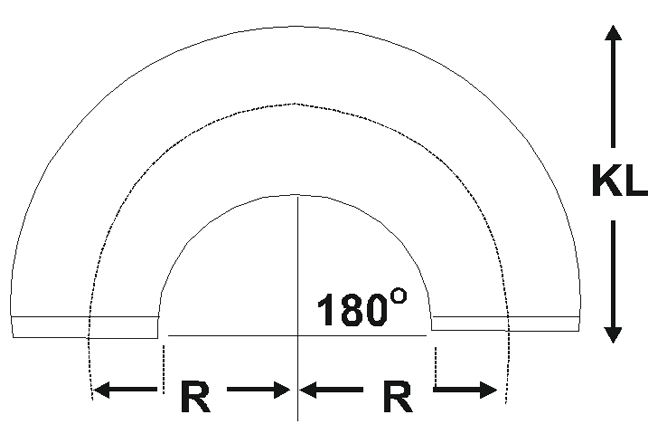

Return Bends

-

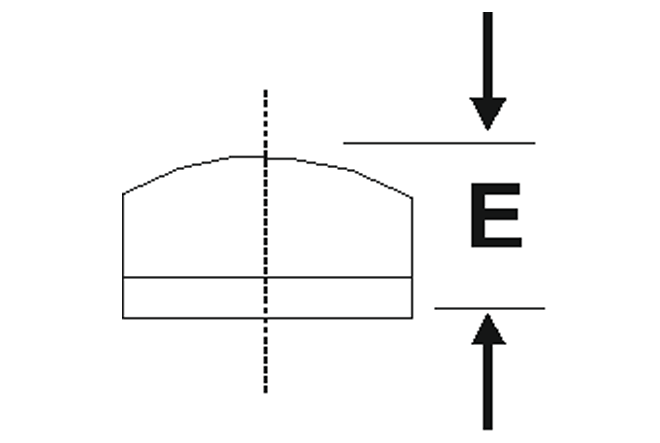

Caps

-

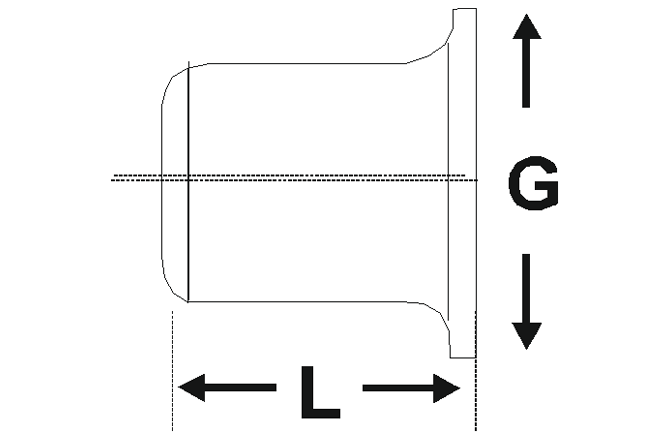

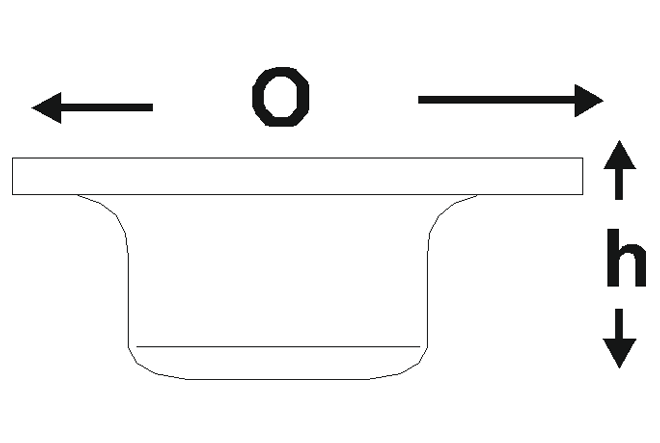

Lap Joint Stub Ends

-

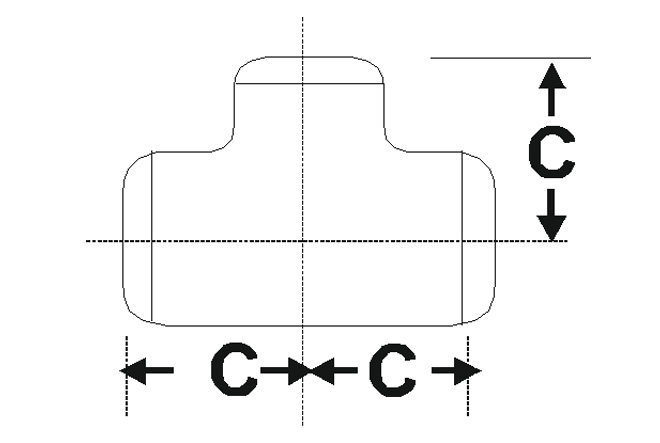

Equal Tees

-

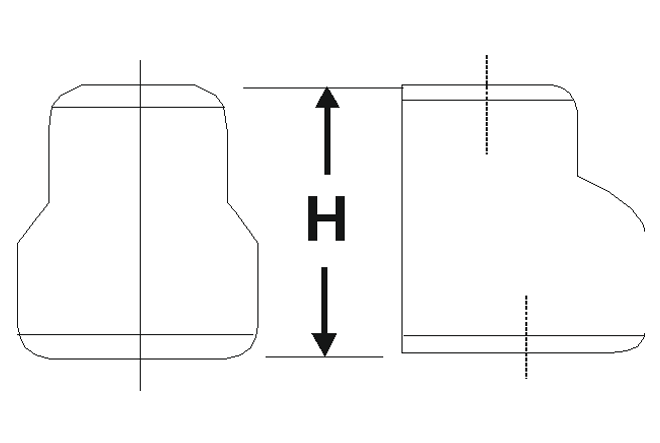

Conc and ECC.Reducers

-

Short Stubends

Butt Welding Fittings to Ansi B16.9, B 16.28

Dimensions of Class 1500 Flanges as Per Ansi B 16.5

|

NOM BORE |

Pipe O.D. |

WALL THICKNESS | RADIUS R | A | B | C | E | G | L | H | D | H | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5S | 10S | 40S | 80S | 1D | 1.5D | 2D | 3D | SHORT | LONG | ||||||||||

| 1/2 | 21.34 | 1.654 | 2.11 | 2.77 | 3.73 | 12.7 | 19.05 | 25.4 | 38.1 | 12.7 | 15.9 | 25.4 | 25.4 | 34.9 | 50.8 | 76.2 | 50.8 | 42 | 8 |

| 3/4 | 26.67 | 1.65 | 2.11 | 2.87 | 3.91 | 19.05 | 28.57 | 38.10 | 57.15 | 19.05 | 11.1 | 28.6 | 25.4 | 42.8 | 50.8 | 76.2 | 50.8 | 52 | 8 |

| 1 | 33.40 | 1.65 | 2.77 | 3.38 | 4.55 | 25.4 | 38.1 | 50.8 | 76.2 | 25.4 | 22.2 | 38.1 | 38.1 | 50.8 | 50.8 | 101.6 | 50.8 | 62 | 10 |

| 1 1/4 | 42.16 | 1.65 | 2.77 | 3.56 | 4.85 | 31.75 | 47.6 | 63.5 | 95.25 | 31.75 | 25.0 | 47.6 | 38.1 | 63.5 | 50.8 | 101.6 | 50.8 | 72 | 12 |

| 11/2 | 48.26 | 1.65 | 2.77 | 3.68 | 5.08 | 38.1 | 57.15 | 76.2 | 114.3 | 38.10 | 28.6 | 57.2 | 38.1 | 73.0 | 50.8 | 101.6 | 63.5 | 82 | 12 |

| 2 | 60.32 | 1.65 | 2.77 | 3.91 | 5.54 | 50.8 | 76.2 | 101.6 | 152.4 | 50.8 | 34.0 | 63.5 | 38.1 | 92.0 | 63.5 | 152.4 | 76.2 | 98 | 16 |

| 21/2 | 73.02 | 2.11 | 3.05 | 5.16 | 7.01 | 63.5 | 95.25 | 127.0 | 190.5 | 63.5 | 44.0 | 76.2 | 38.1 | 104.8 | 63.5 | 152.4 | 88.9 | 118 | 16 |

| 3 | 88.90 | 2.11 | 3.05 | 5.49 | 7.62 | 76.2 | 114.30 | 152.4 | 228.6 | 76.2 | 50.8 | 85.7 | 50.8 | 127.0 | 63.5 | 152.4 | 88.9 | 130 | 18 |

| 31/2 | 101.60 | 2.11 | 3.05 | 5.74 | 8.08 | 88.9 | 133.35 | 177.8 | 266.7 | 88.9 | 57.2 | 95.3 | 63.5 | 139.7 | 76.2 | 152.4 | 101.6 | 140 | 18 |

| 4 | 114.30 | 2.11 | 3.05 | 6.02 | 8.56 | 101.6 | 152.4 | 203.2 | 304.8 | 101.6 | 63.5 | 104.8 | 63.5 | 157.2 | 76.2 | 152.4 | 101.6 | 168 | 20 |

| 5 | 141.30 | 2.77 | 3.40 | 6.55 | 9.52 | 127.0 | 190.5 | 254.0 | 381.0 | 127.0 | 82.6 | 123.8 | 76.2 | 185.7 | 76.2 | 203.2 | 127.0 | 188 | 25 |

| 6 | 168.27 | 2.77 | 3.40 | 7.11 | 10.97 | 152.4 | 228.6 | 304.8 | 457.2 | 152.4 | 95.3 | 142.7 | 88.9 | 215.9 | 88.9 | 203.2 | 139.7 | 215 | 25 |

| 8 | 219.07 | 2.77 | 3.76 | 8.18 | 12.7 | 203.2 | 304.8 | 406.4 | 609.6 | 203.2 | 127.0 | 177.5 | 101.6 | 270.0 | 101.6 | 203.2 | 152.4 | 270 | 30 |

| 10 | 273.05 | 3.40 | 4.19 | 9.27 | 12.7 | 254.0 | 381.0 | 508.0 | 762.0 | 254.0 | 158.7 | 215.9 | 127.0 | 324.0 | 127.0 | 254.0 | 177.8 | 330 | 35 |

| 12 | 323.85 | 3.96 | 4.57 | 9.52 | 12.7 | 304.8 | 457.2 | 609.6 | 914.4 | 304.8 | 190.5 | 254.0 | 152.4 | 381.0 | 152.4 | 254.0 | 203.2 | 400 | 40 |

| 14 | 355.60 | 3.96 | 4.76 | 9.52 | 12.7 | 355.6 | 533.4 | 711.2 | 1066 | 355.6 | 222.2 | 280.0 | 165.1 | 412.8 | 152.4 | 305.0 | 330.2 | - | - |

| 16 | 406.40 | 4.19 | 4.76 | 9.52 | 12.7 | 406.4 | 609.6 | 812.8 | 1219 | 406.4 | 254.0 | 304.8 | 177.8 | 470.0 | 152.4 | 305.0 | 355.6 | - | - |

| 18 | 457.20 | 4.19 | 4.76 | 9.52 | 12.7 | 457.2 | 685.8 | 914.4 | 1372 | 457.2 | 285.7 | 343.0 | 203.2 | 533.4 | 152.4 | 305.0 | 381.0 | - | - |

| 20 | 508.00 | 4.76 | 5.54 | 9.52 | 12.7 | 508.0 | 762.0 | 1016 | 1524 | 508.0 | 317.6 | 381.0 | 228.6 | 584.2 | 152.4 | 305.0 | 508.0 | - | - |

| 24 | 609.60 | 5.54 | 6.35 | 9.52 | 12.7 | 609.6 | 914.4 | 1219 | 1829 | - | 381.0 | 431.8 | 266.7 | 698.5 | 152.4 | 305.0 | 508.0 | - | - |

Standards:

- All dimensions are in mm and confirm to ANSI B 16.9 and MSS. SP-43

Radius:

- Radius of Short Radius Elbows is 1 times nominal pipe diameter, Radius of Long Radius Elbows is 1 ½ time nominal pipe diameter.

Material of Construction:

- S.S 304/304L/316/316L/321 Carbon Steel and Alloy Steel.